What is a Bucket Elevator and Why Is It Essential for Material Handling?

09/05/2025

How to Avoid Film Overuse and Reduce Waste: Best Manufacturing Practices in Bagging Lines

11/06/2025The cement industry is rapidly evolving towards more efficient and sustainable processes, and at the heart of this transformation lie combustion systems. In this context, Unitherm Cemcon burners—represented by Servimex—stand out as a cutting-edge solution thanks to their advanced technology and adaptive capabilities.

What sets Unitherm burners apart?

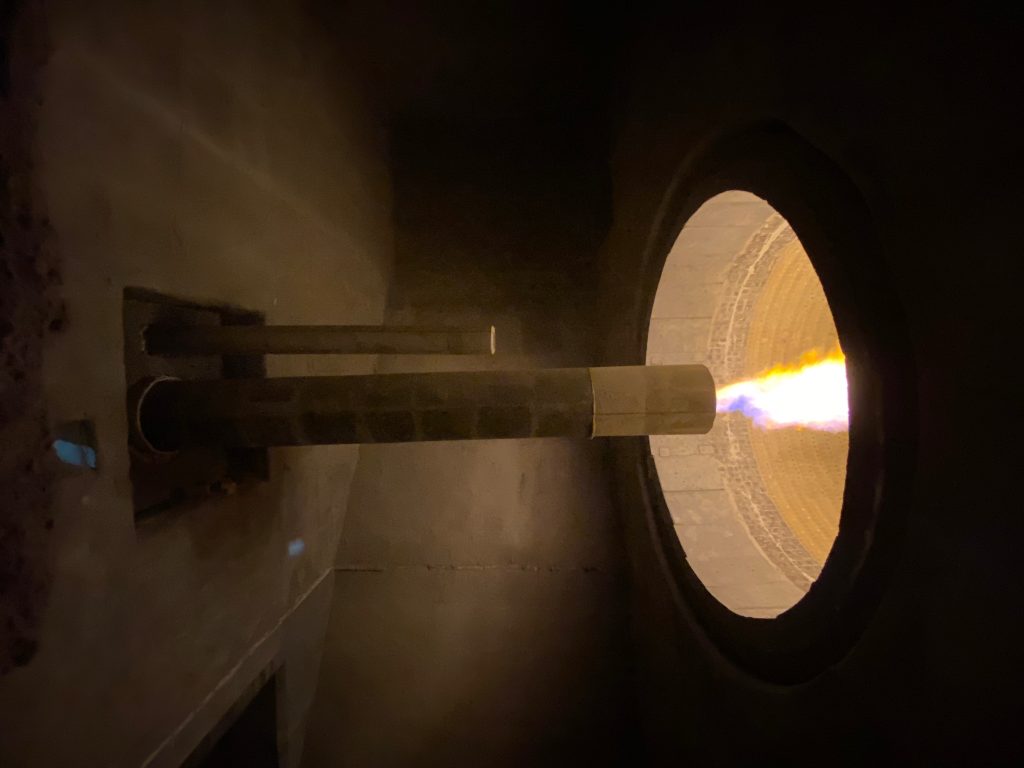

Unitherm has developed the M.A.S© DT (Disc Technology) burner, an innovation that integrates momentum with primary air flow kinematics directly at the burner tip. This proprietary M.A.S© D.T. (Disc Technology) enables more precise flame shapes and higher thermal efficiency, resulting in a more effective flame momentum.

The patented Mono Airduct System (M.A.S©) features a series of adjustable primary air nozzles positioned at a precise projection angle. This results in a flame that is consistently reproducible at any setting and adaptable to various fuels—from natural gas to alternative fuels (AF) such as biomass or industrial waste.

Innovative combustion

The move toward smart combustion is evident: Unitherm’s control systems incorporate PLCs that allow easy and safe management of any flame profile required by the rotary kiln process.

Multi-fuel capability and operational resilience

Unitherm designs burners capable of continuous operation with multiple fuels, including high percentages of AF (>70%). This flexibility leads to significant cost savings for cement plants.

Unitherm’s satellite burners enable the injection of secondary fuels into high-temperature zones, increasing AF usage by up to +50% and maximizing the substitution of primary fuel.

Operational benefits

- Energy efficiency: Reduced electrical and thermal energy consumption.

- Primary fuel reduction: Enhanced use of RDF (Refuse Derived Fuel).

- Optimized maintenance: User-friendly design for easy and fast servicing.

The role of Servimex

As Unitherm’s regional representative, Servimex facilitates the implementation of this technology throughout North America, Latin America, and the Caribbean. In addition to supplying the equipment, they offer training, installation consulting, and remote technical support to ensure burners operate under ideal parameters.

The cement industry is moving forward with a strong commitment to cleaner operations and a reduced carbon footprint. Integrating systems like Unitherm’s is a decisive step toward sustainability and aligns with global environmental goals.

Unitherm’s satellite burners, when combined with the M.A.S© burner, are the perfect equipment to achieve the highest substitution rate of primary fuel with Refuse-Derived Fuel (RDF), turning waste into thermal energy that ultimately becomes a useful product for society.

Want to learn more about this technology? Contact us and discover how to take your process to the next level.

🌐 www.unitherm.at | www.servimex.net